Finishing Plaster

Easy Sand

ŚMIG E-1

HOW DO I SMOOTH WALLS, CEILINGS AND PLASTERBOARDS?

Our product will help you Smooth Walls, Ceilings and Plasterboards! Also ŚMIG E-1 has much more functions. For more info check below.

PRODUCT PROPERTIES

LIGHT GREY COLOUR

ŚMIG E-1 wet and dry layers are light grey.

Easy sanding

Dry E-1 layer is easily to sand manually while maintaining its durability and strength.

Bonding time

Open time

Drying time

A layer of 1 mm takes 2-3 hours to dry at +20°C. The time varies depending on the thickness of the layer, temperature and ambient conditions. Low temperature and thicker layers may prolong drying up to several days. In case the interior lacks ventilation and humidity level remains high, the finish layer may not dry at all.

Layer thickness from 1 to 7 mm

The correct layer thickness is 1 to 7 mm. Note! Do not apply layers thinner than 1 mm. The layer may never reach its strength, since water evaporates before the bonding reaction is completed. Although there is no upper limit for the layer, for layers above 7 mm it is advisable to use gypsum plaster.

ŚMIG E-1 - Finish For Easy Sanding

HOW TO USE

1. Surface preparation

The product may be applied on all typical interior surfaces: gypsum, cement plasters, and lime plasters, gypsum blocks, concrete, aerated concrete, plasterboards and durable paint emulsion, phthalic and oil coatings, provided the surface is stable, clean and dry. The surface should be stable, clean, free of grease, soot, flaking and unstable paint coatings (cleaning with water under pressure or detergents). Wetting of the substrate is not recommended as it reduces the adhesion of the product. No priming is necessary. If the substrate stability is uncertain, it is recommended to use the ŚMIG K-15 Universal Primer.

2. Product preparation

The product should be mixed with water (0.4 l of water per 1 kg of product) and mixed with a slow mixer and agitator suitable for gypsum finish. During preparation, use clean, preferably potable water. Put product into water, never the other way round. Mix until you reach uniform mass of desired density. After 2-3 minutes, the mixture is ready for use. Too thin or too dense mortar may be corrected during the initial 10 minutes by adding the dry product or water and mixing. To prepare mortar, use stainless containers free from any remains of solidified gypsum.

3. Application

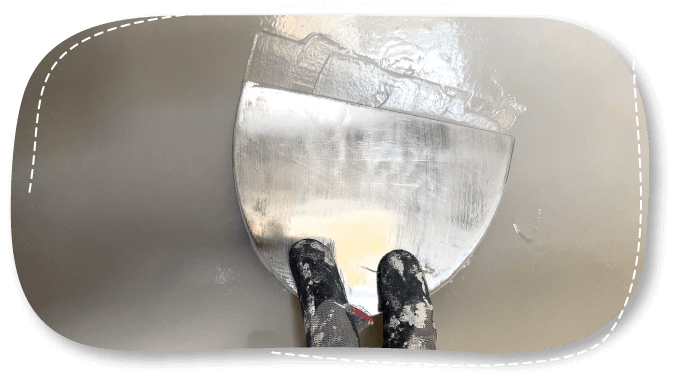

Apply mechanically or manually using clean stainless steel tools. It is recommended to fill larger cavities before applying the product to a larger surface. Working temperature ranges between +5 and +30°C.

4. Dry sanding

It involves putting one or two layers of wet finish and sanding unevenness after drying. Initial sanding with 80-120 grit sand paper or mesh. Final grinding with 180-240 grit sand paper or mesh. If the first layer is not even, it is recommended to add the product locally or apply its thinner layer. Before applying another layer and before painting, it is essential to remove dust from the surface or to bond it to the surface. When removing dust, use clean brushes and the ŚMIG K-15 Universal Primer. Primer must be applied using a paint roller or a spray gun. After removing dust or drying of the primer, the smooth surface is ready for painting.

Dry mixture of natural gypsum with lime fillers and upgrading, modifying, and retarding additives and admixtures that ensure excellent adhesiveness. Gypsum bonding content less than 50% of the weight.

Compliance: EN 13279-1:2008; EN 13963:2005; EN 13963:2005/AC:2006

Bonding time: 90 min.

Reaction to fire: Class A1

Water to product weight ratio: 0.4:1

Capacity: 1 kg/dm3

Spreading capacity: approx. 1 kg/1 m2/1 mm

Application temperature: +5 to +30°C

Storage temperature: 0 to +40°C