Ready Mixed White

NO TAPE Jointing Compound

ŚMIG C-50

HOW DO I CONNECT PLASTERBOARDS?

Our product will help you connect plasterboards! Also ŚMIG C-50 has much more functions, like for example fixing holes. For more info check below.

Product properties

PERFECTLY WHITE

ŚMIG C-50 in the form of wet paste or when dried remains white.

Flexible and resistant to cracks

Due to polymer networks after drying and bonding, ŚMIG C-50 is highly flexible and resistant to cracking. NOTE! The product reaches its structural stability, flexibility and adhesion only after drying and bonding have been completed.

Economical and convenient

ŚMIG C-50 is intended for immediate use after opening of its packaging. Work can be interrupted at any time by tightly closing the bucket. Next time after opening, the product can be used again. ŚMIG C-50 should be applied straight from the bucket without any preparation. This makes the product very convenient to use and saves up to 10% of time (no need for traditional gypsum mortar preparation). Thanks to the use of the entire bucket content, the product is also more economical than traditional mortars. When preparing a mixture from dry product, it often happens that a large part of the material is not used, solidifies and is not suitable for use. With the ready-made products, you can avoid the waste, as you take from the bucket only material that is needed. The rest can be used later, provided you close the packaging tightly.

Layer width

Pre-fabricated plasterboards should be fitted with a gap of 3-5 mm. When cut, edges of plasterboards should be profiled at 45°, treated with K-15 primer and fitted while maintaining a gap of 1-2 mm.

Bonding time 2 h

The mortar bonding time is approximately 1-2 hours for a 1 mm layer and approximately 24 hours for a 5 mm layer (at +20°C and with good ventilation). The bonding time may increase or decrease depending on the temperature. A temperature below +10°C stops bonding.

Jointing strength

Joints are susceptible to cracking due to the low strength of joints traditionally made from gypsum putty and paper tape. Its strength is about 320 N, while the strength of a typical plasterboard is on average 520 N. ŚMIG C-50 reinforced with a polymer network guarantees higher strength even without tape.

ŚMIG C-50 - Extra Strong Jointing Compound!

ŚMIG C-50 can be used with prefabricated and manually cut plasterboards. Its high flexibility and strength ensures durability of joints without reinforcement tape. ŚMIG C-50 is also used for filling, patching and chasing in small and large areas of walls and ceilings,

ŚMIG C-50 functions

PLASTERBOARDS JOINTING

ŚMIG C-50 can be used with prefabricated and manually cut plasterboards. Paper tape should be used on inner corners. The additional application of the paper tape increases the strength of the bond, so it becomes stronger than the plasterboard itself!

FILLING

C-50 is designed for filling, patching and chasing in small and large areas of walls and ceilings. Size of one layer should be up to 5 mm. After drying, apply the second layer.

Installing Corner Beads

C-50 is also designed for installing corner beads. Add corner bead on wall with layer of wet compound and finish!

See for yourself how easy using ŚMIG C-50 is!

Jointing of plasterboards without reinforcement tape!

ŚMIG C-50 will be perfect for places particularly exposed to deformation, such as attic ceilings. By providing a flexible connection, we will avoid cracks in less resistant places on ceilings and walls.

ŚMIG C-50 has an innovative structure based on a polymer chain net, which provides additional strength and unique elasticity. The polymer net strengthens the jointing, and thus the reinforcement tape is no longer needed. In other words, the bond made with ŚMIG C-50 has much higher fracture toughness, without using the reinforcement tape than traditional gypsum putty joints.

Jointing strength

Tests were performed to European standard EN13963 546 point 5.8.1 by the „until the first cracks” method.

710 kg/m

- Prefabricated edges

- C-50

780 kg/m

- Prefabricated edges

- K-15 Universal Primer

- C-50

900 kg/m

- Prefabricated edges

- K-15 Universal Primer

- C-50

- Paper tape

1100 kg/m

- Manually cut edges cut at 45°

- K-15 Universal Primer

- C-50

- Paper tape

how to use

1. Surface preparation

Prepare contact surfaces of plasterboards before jointing. The boards should be firmly attached to the supporting structure, dry and free of dust. Cut edges, remove dust, and treat the surface with the ŚMIG K-15 Universal Primer. In corners and angles, mount angle brackets.

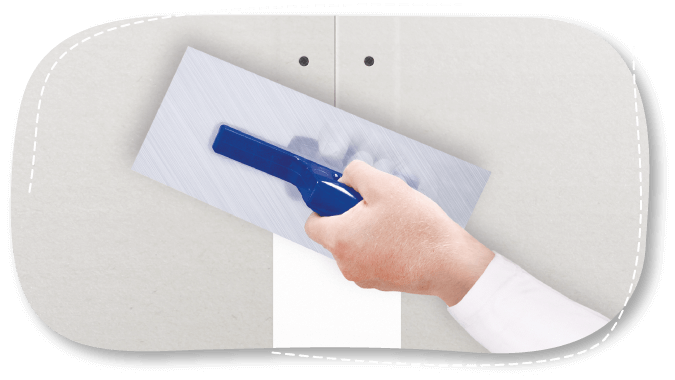

2. Jointing of plasterboards without reinforcement tape

Fill the space between the edges with C-50 using a spatula at an angle to allow the product to be accurately pressed into the gap. Allow to dry. After 24 hours, apply another layer of C-50. The final smoothing should be provided after the product has completely dried by sanding with a polycarbonate mash or 80-150 grit sandpaper. To facilitate sanding, it is recommended to use ŚMIG A-2 or A-6 finish for the finishing coating. Dust must be removed or bound with K-15 multipurpose primer before applying another layer of the product or a paint coating. To obtain the desired quality of the paint coating, it is also recommended to reach the same absorption capacity of plates and joints by treating them with ŚMIG K-15 Universal Primer.

3. Filling, patching and chasing in mineral plasters

Surface repair must be carried out by pressing the product into a cavity, provided that the cavity does not exceed 5 mm. After drying, apply the second layer. For perfect smoothness, grind the surface with polycarbonate mesh or 80-150 grit sandpaper. Dust must be removed with the ŚMIG K-15 primer before applying another layer of the product or paint coating.

Chemical composition: mixture of mineral materials, polymer dispersion, chemical additives and water, with the texture of thixotropic paste.

Compliance: EN 13963:2005, EN 13963:2005/AC:2006

Adhesiveness to plasterboards: ≥ 0.25 N/mm2

Reaction to fire: Class A2-s1, d0

Specific gravity: 1.5 kg/l

Application temperature: +10 to +40°C

Storage temperature: 0 to +40°C

Capacity on plasterboards with prefabricated edges: 0.4 kg/m

Capacity on plasterboards with 45º cut edges: 0.3 kg/m

Capacity per unit area: approx. 0.5 kg/m2

1 mm layer bonding time: 1-2 h at +20°C and 50% humidity

Maximum joint width: 5 mm